In many companies, lifecycle management still involves manual steps. Maintenance logs, configurations and service reports are kept on paper, stored in binders, spreadsheets or local folders.

Machine books are updated by hand. Maintenance records are incomplete. Configuration changes are rarely documented. That makes collaboration harder, leads to mistakes and results in information loss, which causes problems during retrofits, audits, or when legal documentation is required.

All key information from your global fleet is centrally managed and always available – from master data and digital machine logs to complete service and configuration histories. Maintenance schedules are based on real data. Safety checks are easier to plan. Configuration errors during commissioning are avoided.

This improves teamwork and provides more transparency, control and legal certainty throughout the machine’s lifecycle.

What Sets Machine Lifecycle Management With EquipmentCloud® Apart?

You benefit from a consistent, complete, and always-available data foundation that spans the entire machine lifecycle:

- Everything in one place: Master data, configurations, technical documentation, maintenance logs and spare parts lists are centrally organized. This saves time and improves coordination.

- Full visibility: You always have access to current data and stay on top of machines, locations and workflows.

- Complete documentation: No more lost information. Record everything in a traceable and audit-proof way.

- Reliable data: With structured, transparent information, your insights are solid: Internally and when working with customers.

- Improved service: You reduce response times, make better decisions, and increase customer satisfaction through a dependable data foundation.

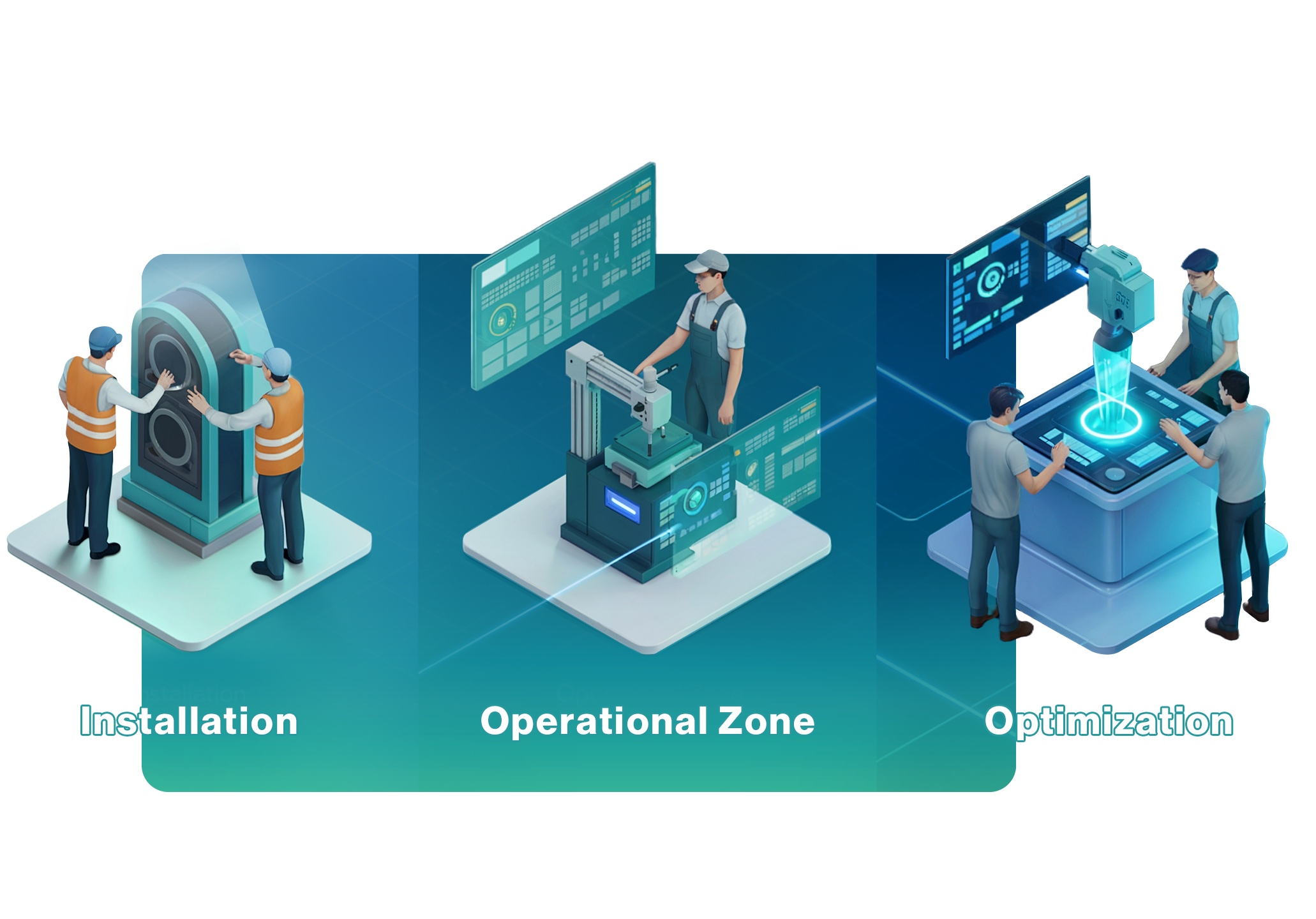

This Is What Successful Lifecycle Management Looks Like in Three Phases

1. Commissioning

Use all available data from development and project execution right from the start. Add configurations, FAT results, and derived tasks. Everything is centrally recorded, clearly documented and accessible to everyone involved.

2. Operation

Monitor machine condition continuously. Evaluate historical data and track shift operations in the logbook. This helps you spot patterns faster, schedule maintenance more effectively, carry out repairs on time and prevent long, unexpected downtimes

3. Optimization and modernization

Identify potential early, evolve your machines based on data, and extend their service life with planned upgrades. This is a key part of your digital service offering

Integrated Spare Parts Management That Drives Revenue

A critical part of machine lifecycle management is managing spare parts. Together with Quanos, EquipmentCloud® offers the SpareParts Pro add-on module to help you identify, manage, and process spare parts orders efficiently.

It’s also used in service and support for training purposes. It simplifies picking processes and ensures accurate documentation of actual wear and replacement parts during maintenance and repair.

Quickly identify parts with clear 3D views, based on CAD data, ERP systems, electrical plans, or PLM.

Move directly from the machine view to the matching spare parts list without any system jumps. Integrated user and access management ensures the right catalog is tied to the right machine.

Track and manage wear and spare parts orders easily with built-in ERP connectivity. Keep your customers informed throughout the entire order process.

Reliable consumption and order data help you plan critical spare parts in advance and reduce storage costs.