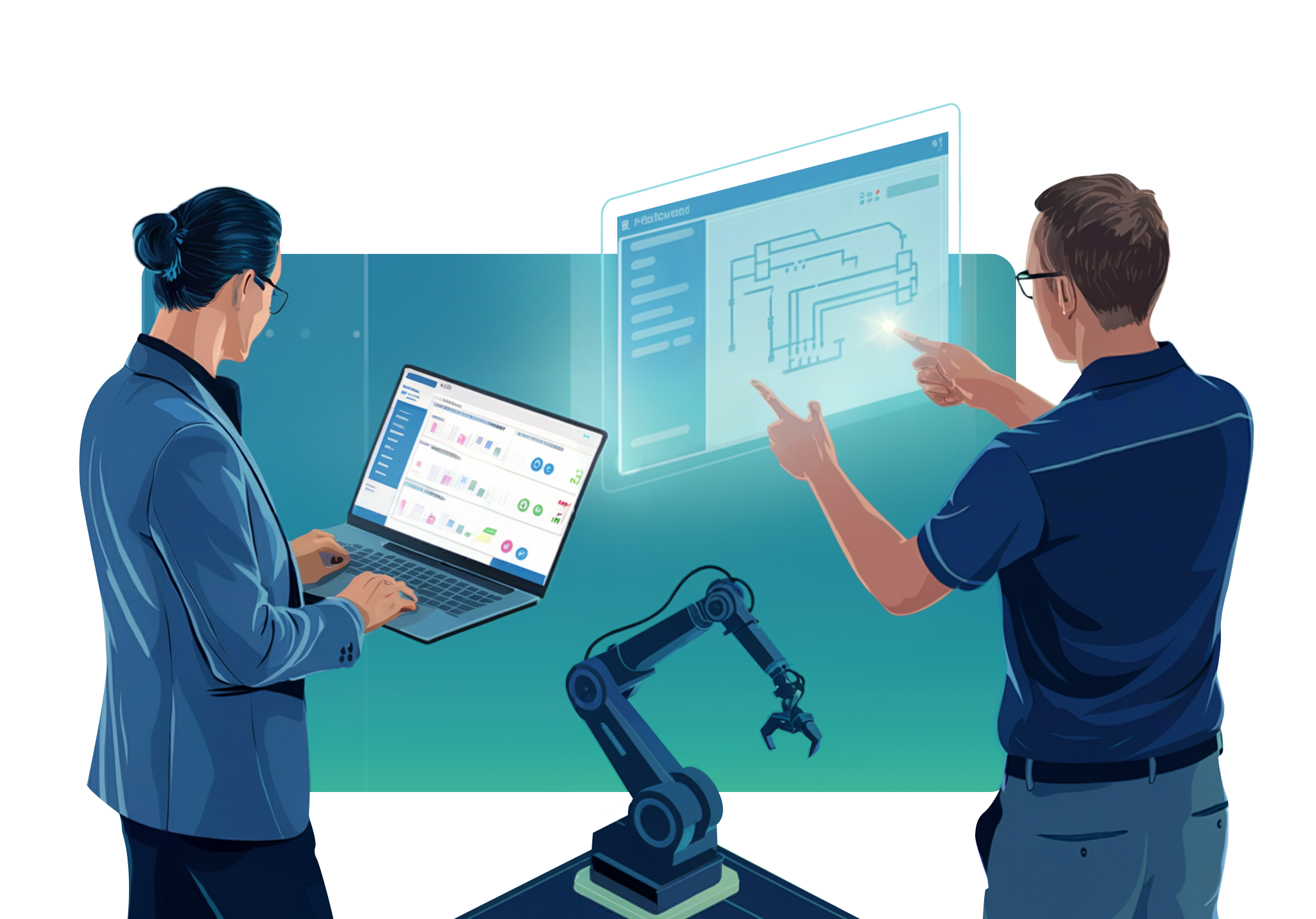

Service requests came through many different channels – often unstructured. Information was scattered. Maintenance was reactive. Downtime was hard to predict, and data lived in silos.

The result: high effort, rising costs, frustrated customers.

With EquipmentCloud®, everything connects.

Customers, service teams, and partners work on one platform. All the information is where it belongs – up to date, traceable and instantly available.Requests come in through structured channels and processes connect seamlessly. This makes service more predictable, more efficient and more transparent for everyone involved.

What Does a Digital Customer Portal Enable?

- Faster response times: Requests are logged in a structured way, supported by built-in applications, and resolved faster.

- Better overview: Alle relevanten Daten zu Maschinen, Anlagen und Ersatzteilen sind jederzeit abrufbar.

- Improved customer communication: Everyone stays on the same page – centrally and in real time for your customers.

- Third-party software integration: Connect your customer portal easily with existing ERP, technical documentation, PDM, CRM, DMS or spare parts systems.

- More after-sales potential: Boost spare parts sales with digital catalogs or introduce new digital services. Your team becomes a true service partner.

- White-label solution: Offer your customers a platform in your brand’s look and feel – fully customized.

Work More Efficiently With Less Effort

Instead of wasting time searching for info, your team accesses everything directly through the customer portal, from digital machine files and service history to maintenance plans. An integrated ticket system ensures all inquiries are handled in a clear and structured way.

That means fewer delays, no unnecessary follow-ups, and quicker resolutions from the start.

Boost Customer Satisfaction with Simple Self-Service

Give customers access to the information they really need, whenever they need it: spare parts catalogs, technical documentation, repair guides, or maintenance videos. That saves your team time and makes life easier for your customers.

Make Machine Data Truly Useful With Condition Monitoring

Machine data is critical for efficient, forward-looking production. The challenge is to provide it in a way that integrates cleanly with your customers’ systems, like MES or control systems.

As an equipment manufacturer, you lay the groundwork with a standardized interface. And with the RESTful API-based EquipmentCloud® portal, you benefit on both ends:

You receive pre-filtered, aligned machine data like status updates, reference values, alarms, events or process-related calibration data. At the same time, this opens the door to new digital services and future-proof business models.