We all know that time is money — this is especially true in mechanical engineering. Every downtime, any unplanned disruption, can result in costly delays and limit production capacity. Efficient maintenance processes are therefore the key to success in this highly complex and demanding industry.

Imagine being able to reduce the time required to document your maintenance work to a minimum without sacrificing accuracy. What if you could track the progress of your maintenance work in real time, without having to jump back and forth between different systems?

But how can you achieve this and make maintenance documentation easy?

The maintenance module of the EquipmentCloud® digital transformation solution makes efficient documentation of routine maintenance tasks possible — with no time-consuming, unnecessary clicks. In this blog post, we take a look at the challenges facing experienced maintenance teams from cross-industry mechanical engineering companies, whose valuable feedback has helped us take development of the maintenance module to a new level.

Between time pressure and precision: maintenance challenges

In the dynamic environment of mechanical engineering, maintenance workers face a variety of tough challenges when carrying out maintenance work:

1. Efficient and speedy documentation of regular maintenance

Every maintenance job requires a precise record of the measures taken so that the maintenance team can ascertain the status of the systemat any time. However, traditional documentation methods often prove to be time-consuming and prone to errors. If maintenance staff are confronted with extensive paper documentation or complex digital systems, valuable time is lost which they could use more profitably doing their actual job — carrying out the maintenance and repair of the machines.

2. Make best possible use of set-up times to avoid unnecessary production interruptions

In the manufacturing industry, every minute of production time is invaluable. It is therefore crucial to use set-up times efficiently so as not to interrupt production unnecessarily. In numerous industries, such as the solar industry, production runs round the clock, so that maintenance is only possible within a time window of 15 minutes when retrofitting. Experienced employees know exactly how maintenance works and therefore want to avoid extra clicks in order to save time.

Consequently, maintenance work must be planned and carried out in such a way that it fits seamlessly into the production process and does not cause unnecessarily long machine downtimes. For this, precise planning and a sophisticated maintenance system are needed so that maintenance work is coordinated as efficiently as possible.

3. Support experienced maintenance staff and new employees in performingand documenting maintenance

Maintenance teams are often made up of experienced maintenance staff and new team members. The challenge is to support both groups equally as they perform and document maintenance. Experienced team members often have numerous tried-and-tested procedures, techniques and great knowledge which, however, may not be fully integrated into a system. New colleagues, on the other hand, must quickly learn the processes and build up extensive knowledge so they can perform maintenance work with minimal disruption.

4. Keep a closer eye on the progress of maintenance

Tracking the progress of ongoing maintenance and repair work is critical to ensure that no important tasks are missed and that all work is completed properly. But in large systems with many tasks it can be difficult to keep track of the current status of the individual maintenance tasks.

5. Keep a record of unforeseen repairs

In a dynamic production environment, unforeseen repairs and faults can occur at any time. Such events require prompt action and accurate documentation to resolve issues efficiently and minimize potential downtime. An effective solution must log repairs quickly and accurately in order to provide complete information on the status of the machine, even under time pressure.

6. Keep a record of maintenance that has not been carried out

Time and again, planned maintenance cannot be carried out. There are various reasons for this, such as production bottlenecks, material shortages or other unforeseeable events. However, full records must be kept of any maintenance work that has not been performed to ensure a complete maintenance history and understand potential effects on machine performance.

The solution: The maintenance module of the EquipmentCloud® digital transformation solution

The solution to these various maintenance documentation challenges lies in close cooperation with users from the mechanical engineering sector. We are convinced that the best innovations come about when we understand the needs and perspectives of those who work with our digital transformation solution on a daily basis. From the outset, the input of maintenance staff was at the heart of our development process. Through surveys and personal discussions we received valuable feedback, which helped us to identify the most important problems and needs and tailor the maintenance module precisely to them.

To ensure the quality of EquipmentCloud® and accelerate the development process, we use agile development methods. Close cooperation with users enables us to react quickly to their requirements and implement new functions promptly. This gives users the opportunity to provide feedback at an early stage and actively contribute to the development.

The maintenance module has been redesigned to ensure excellent usability. Every click and every action was carefully evaluatedand, if necessary, redesigned to enable maintenance staff to work intuitively and efficiently.

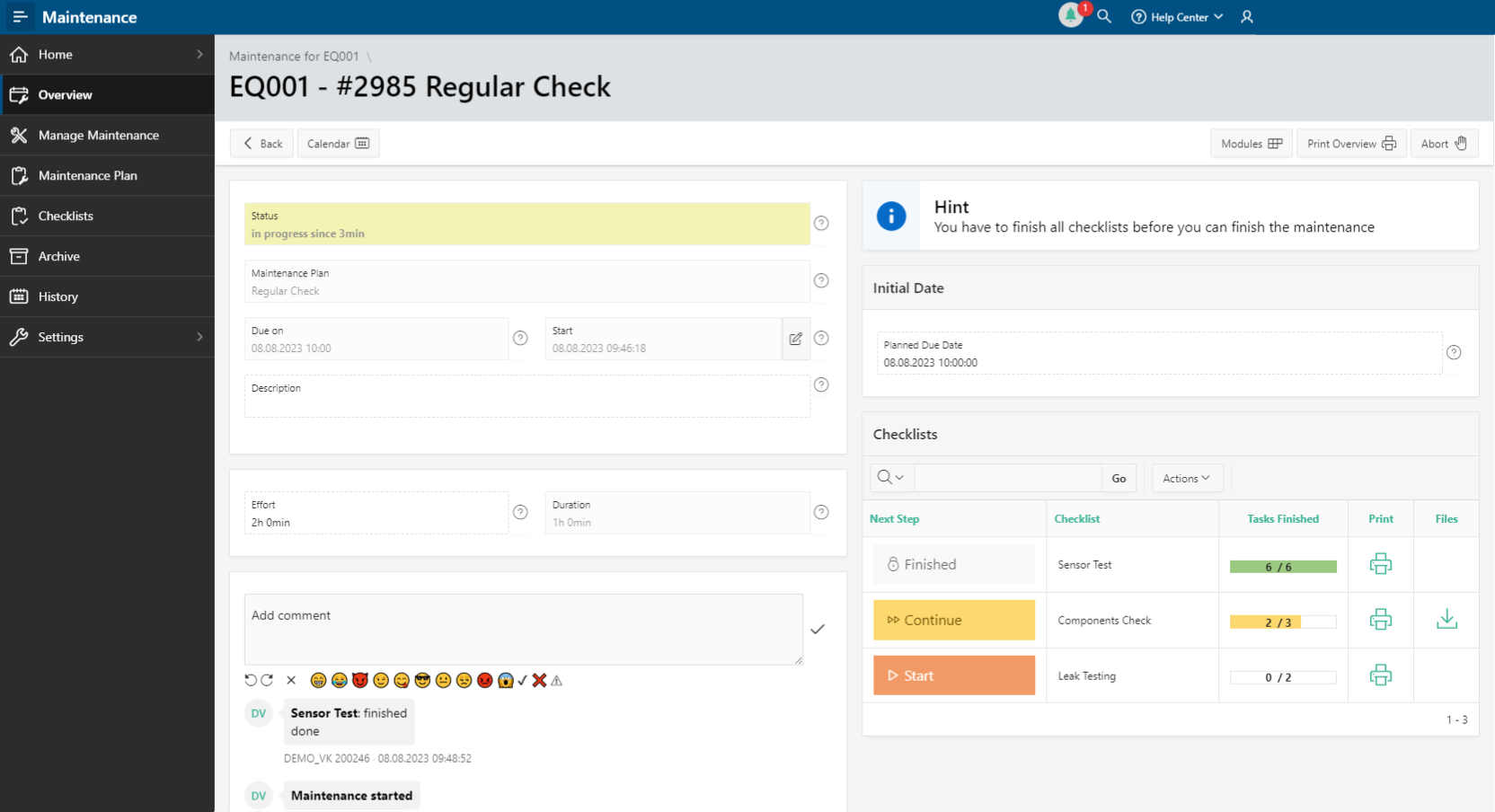

In the next section, learn about the new features that take the module to a new level. From efficient checklists and clear status displays to innovative operating concepts for the mobile app — the revised maintenance module has given numerous functions and improvements to EquipmentCloud® that revolutionize the work of maintenance staff.

The key feature: Complete checklists in 4 clicks

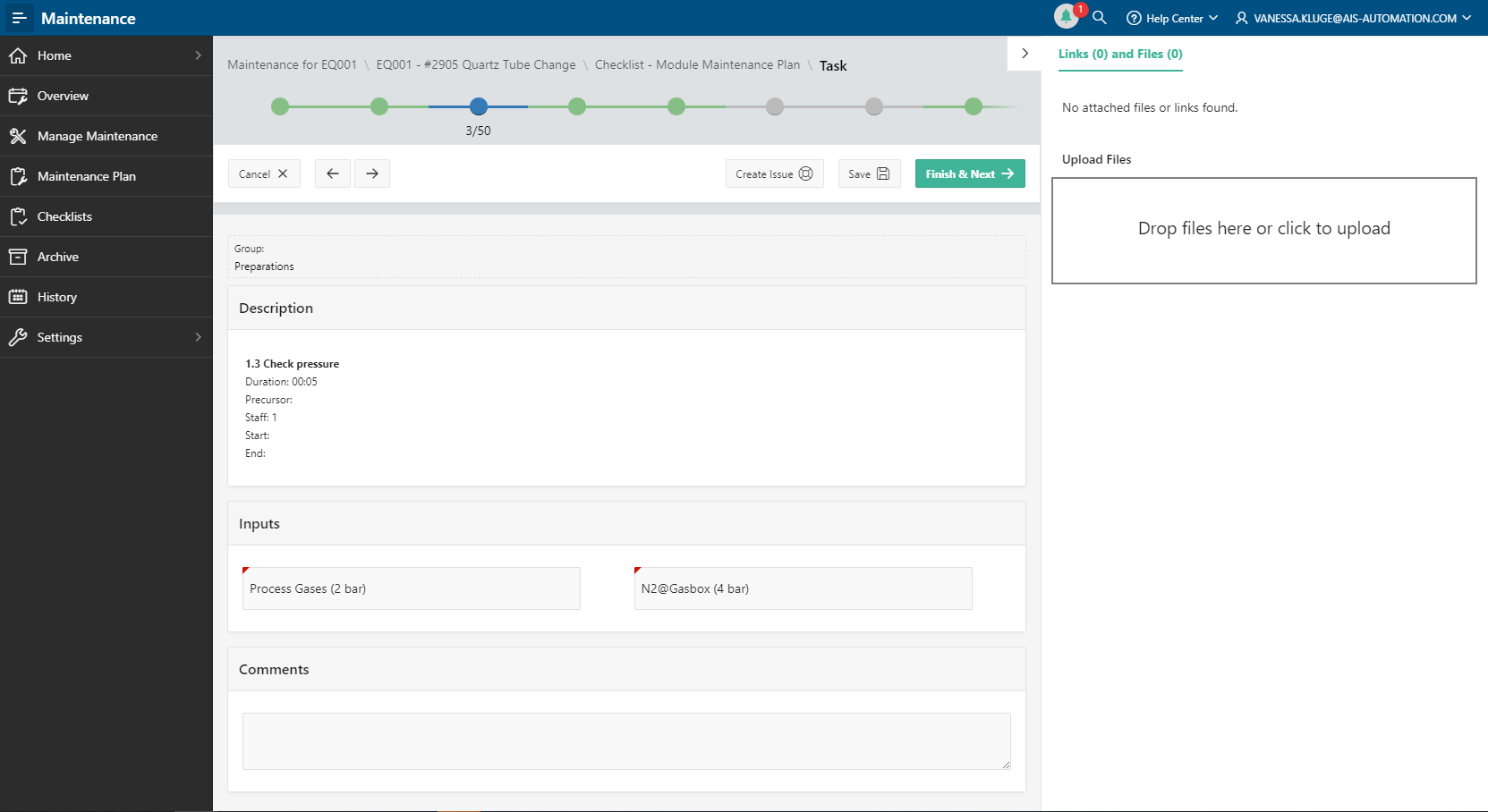

Maintenance can now be carried out using optimized checklists. Our new progress bar shows the operator exactly how much he has already completed.

Maintenance is completed with just four clicks, saving valuable time. The process is very simple: Maintenance is started (1), the checklist is opened (2), the individual tasks are checked off (3), and maintenance is ended (4). Tasks that only need to be checked off are completed with one click; when entering text, the system takes users straight to this task to speed up documentation. This allows users to concentrate fully on their tasks and spend less time on complicated navigation.

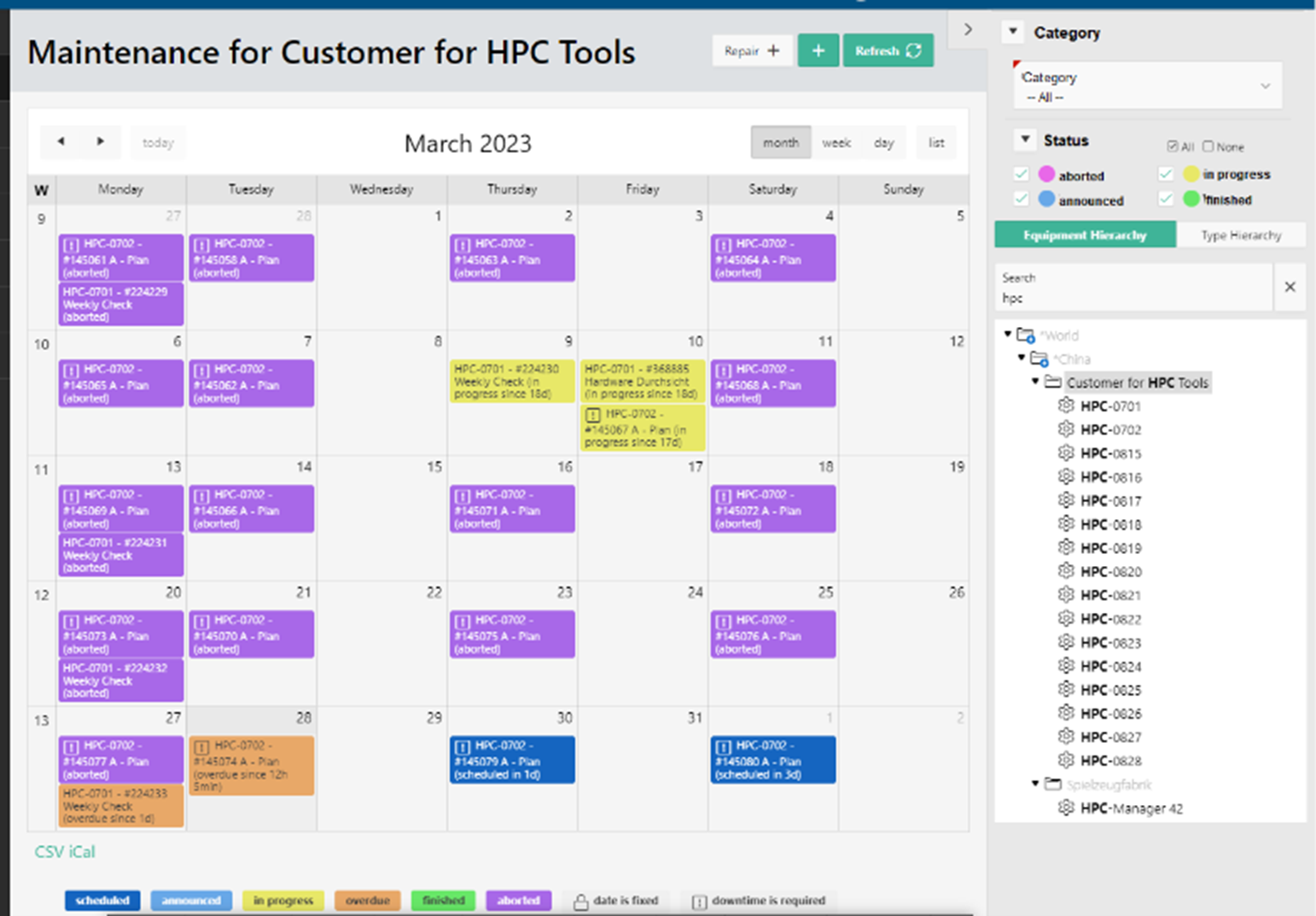

A clear overview — status of maintenance and repairs

To keep track of the maintenance calendar, we have introduced a clear display for canceled or unperformed maintenance. This is given its own status so that those responsible can act quickly. A new status and category filter helps maintenance staff select the relevant upcoming maintenance for a day, week, or month quickly and easily in the calendar or list view.

Another milestone in our development is the new maintenance type “repair.” This does not require a checklist and can be planned straight from the maintenance calendar or started directly. Maintenance that has been postponed several times is automatically set to “canceled” as soon as new maintenance is scheduled. In this way, maintenance staff do not have to worry about dealing with obsolete maintenance tasks and at the same time retain planning security at all times.

Flexibility and convenience — new features for smooth maintenance

Meter-based maintenance can now be planned on the basis both of values and time to meet individual requirements. In addition, we enable straightforward evaluation by displaying the due date and performance date of maintenance.

It is now possible to switch flexibly between different checklists when they are assigned to a maintenance job. Instructions with images have also been introduced which, along with the written information, make performance easier. In this way, complex maintenance processes can be presented step by step for ease of understanding, making it easier to train new employees and enabling faster and more precise maintenance for the entire team.

Our goal is to give maintenance staff and machine operators more freedom in the way they work. In this way, maintenance can be started ahead of time and managed through the advance notice period. The result is efficient, clear, and user-friendly maintenance documentation.

High usability on all devices thanks to the new EquipmentCloud® mobile app

To meet the requirements of today’s working world, we have developed a completely new operating concept for our mobile app. This includes, among other things, various pop-up slide elements for filter selection and execution of actions which intuitively guide operators through maintenance step by step. Thanks to the optimized design, maintenance staff can now carry out maintenance quickly and efficiently in EquipmentCloud® using mobile devices such as a tablet or smartphone.

The future of maintenance documentation in mechanical engineering starts here

Efficient maintenance processes are the key to success in mechanical engineering. Optimized maintenance documentation can prevent costly delays and increase production capacity. The maintenance module of the EquipmentCloud® digital transformation solution offers ways of meeting the many challenges of maintenance documentation and implementation. In close cooperation with experienced maintenance staff, the module was specifically developed to best reflect their needs and perspectives into account as much as possible.

The new features of the maintenance module focus on efficiency and user-friendliness. With optimized checklists, maintenance can be carried out with just four clicks, and a clear overview shows the status of maintenance and repairs. Flexible meter-based maintenance, clear instructions with images, and an intuitive mobile application make it easy to perform and document maintenance work.

This is where the future of maintenance documentation in mechanical engineering begins. With time savings, clarity, flexibility, and usability we give maintenance staff the freedom to concentrate on their actual job: servicing and repairing machines. Because ultimately, every minute counts and time really is money.

Do you want to significantly reduce the time your team spends on maintenance ? See the advantages of the maintenance module for yourself in our free 30-day trial.